New Brochure Available — Download Now: Discover how Geoquest’s TechSpan® precast concrete arches are transforming tunnel, underpass, and crossing construction across Australia and New Zealand. Download the TechSpan® Precast Concrete Arches Brochure

Innovative Tunnel and Crossing Solutions for Australia and New Zealand

Across Australia and New Zealand, engineers and contractors are seeking faster, safer, and more sustainable ways to construct tunnels, crossings, and underpasses. Geoquest’s TechSpan® Precast Concrete Arches are supporting this transformation — delivering an efficient, durable, and proven system for infrastructure and mining applications.

Developed and patented by Geoquest, TechSpan® combines advanced structural engineering with rapid installation and long-term reliability. With more than 60 years of Geoquest expertise behind it, TechSpan® is an efficient and effective buried concrete arch tunnel and crossing solution.

What is TechSpan®?

TechSpan® is an advanced precast concrete arch system designed using funicular curve principles — the most efficient natural shape for distributing loads. Each arch is custom-engineered to minimise bending moments and tensile stresses, achieving maximum strength with minimal material use.

Available as a three-hinged, two-piece system or single-piece arch, TechSpan® can be tailored for spans between 8 and 22 metres. With a 100-year design life, this system offers exceptional durability and structural performance in demanding environments such as live rail corridors, mining operations, and transport infrastructure.

Why Choose Precast Concrete Arches for Tunnels and Crossings?

- Fast and Efficient Construction

TechSpan® allows for installation of 10–20 linear metres per shift, minimising disruption to existing roadways, rail lines, and mine sites. With precast components delivered ready for assembly, contractors can achieve faster project timelines, lower labour costs, and improved safety outcomes.

- Strength Under Heavy Loads

Each TechSpan® tunnel or crossing is engineered using finite element modelling (FEM) and funicular curve theory, enabling superior load capacity and resilience under high fills, steep slopes, and heavy live loads — ideal for mining haul roads, conveyor tunnels, and underpasses.

- Custom-Engineered Solutions

Geoquest engineers optimise every TechSpan® arch to match site-specific conditions, clearance envelopes, and geometric requirements, ensuring the best possible performance, cost-efficiency, and adaptability.

- Durability and Longevity

The curved, funicular design minimises structural stress, resulting in high resistance to overload, corrosion, and aggressive environments. Combined with Geoquest’s controlled precast concrete production, the system ensures a long service life and minimal maintenance requirements.

- Sustainable and Cost-Effective

Factory-based production ensures consistency, quality, and reduced waste. With a narrow site footprint and efficient material use, TechSpan® delivers tangible environmental and lifecycle cost benefits.

Where TechSpan® Excels

TechSpan® technology has revolutionised tunnel and crossing construction across sectors such as:

- Rail and road underpasses

- Reclaim and conveyor tunnels

- Mine access and haul road crossings

- Waterway culverts and stormwater tunnels

- Utility and service crossings

- Blast protection and defence infrastructure

TechSpan® structures can be installed beneath live transport corridors or active sites, eliminating the need for costly closures and significantly reducing project downtime.

Proven Performance on Major Projects

Rozelle Interchange – Sydney, NSW

Part of the WestConnex motorway network, the Rozelle Interchange used multiple TechSpan® tunnel structures to streamline construction in one of Sydney’s most complex infrastructure environments.

Geoquest delivered:

- Two TechSpan® tunnels

- Five MSE walls

- Over 100 precast road and bridge barriers

- Two wire walls and two precast bridge headstocks

Quindanning Mine Infrastructure Project – Boddington, WA

Featuring one of the largest precast concrete arches in the Southern Hemisphere, this TechSpan® tunnel spans 21 metres wide and 37 metres long, enabling safe, durable crossing of a public road under heavy mining loads. The structure was installed on site in just two days, showcasing TechSpan®’s unmatched efficiency.

How the TechSpan® System Works

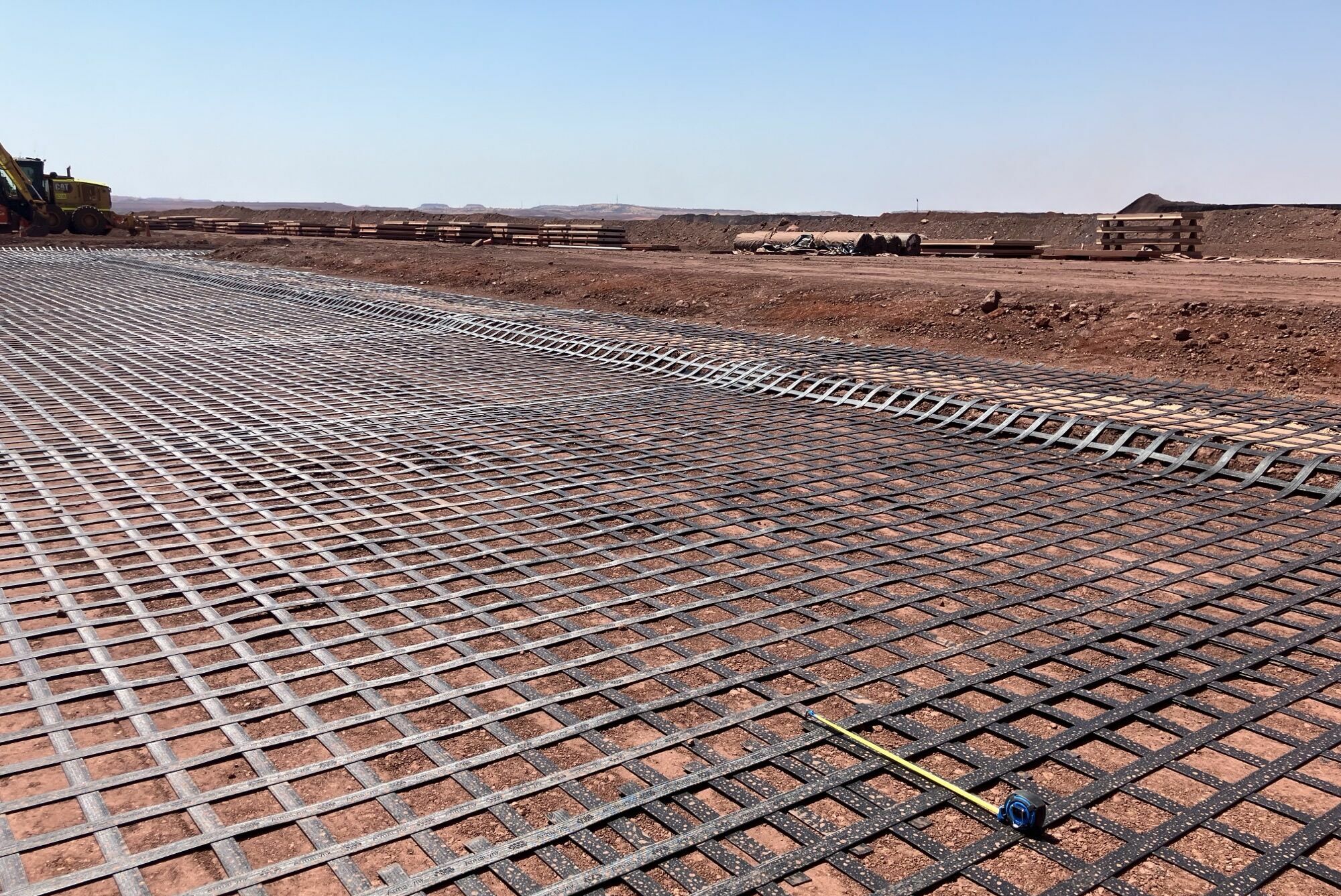

Each TechSpan® tunnel or crossing system comprises:

- Cast-in-place footings to anchor the arch structure

- Precast concrete elements, engineered for specific span and load requirements

- Geotextile and impermeable membranes for protection and watertightness

- Crown and footing joints, sealed for stability and performance

- Specified backfill materials, ensuring optimal load transfer and durability

Geoquest provides a complete turnkey package — from design, certification, and manufacturing to on-site technical guidance — ensuring smooth project delivery from start to finish.

The Advantages of TechSpan®

Strength and Capacity

- Withstands high fills and heavy live loads

- Suitable for rail, road, and mining applications

Efficiency

- Rapid installation with minimal site disruption

- Reduced construction time and overall cost

Customisation

- Tailored geometry and reinforcement to site needs

- Optimised for clearance and operational requirements

Durability

- 100-year design life

- Exceptional resistance to overload and corrosion

Sustainability

- Reduced material waste and smaller footprint

- Factory-controlled production for environmental efficiency

Partner with Geoquest

With more than 60 years of civil and geotechnical engineering expertise, Geoquest Australia is a trusted leader in precast concrete tunnel systems, soil-structure interaction design, and advanced infrastructure solutions.

Our projects span roads, rail and mining infrastructure, delivering innovation, safety, and sustainability across Australia and New Zealand.

Discover the complete TechSpan® range and design your own tunnel or crossing today.

Download the TechSpan® Precast Concrete Arches Brochure

Visit our TechSpan® website page for more information and to design your own TechSpan® concrete arch using our innovative design tool.